Bimp — an accounting system that changes the approach to production automation

Bimp — an accounting system that changes the approach to production automation

Managing production processes requires modern and flexible solutions. The "Production" module based on the Bimp ERP system is a powerful tool for automating all stages at the enterprise. The accounting system enables effective control, accounting, and analysis of production activities.

The Bimp accounting system offers a comprehensive approach: manage all production stages from planning to finished product release in a single convenient system.

MES module "Production": functionality

- Production process planning. Control raw material stocks and create production plans, calculate time and costs for manufacturing products. Also track expenses, product cost, and create integrations with suppliers.

- Equipment condition monitoring. Timely send equipment for repair and maintenance.

- Accounting and expense control. Implement accounting for materials, components, and finished products.

- Analytics. Use an automated interface to collect and analyze data from all production stages.

Integration of production accounting with other ERP system modules: warehouse, finance, purchasing helps businesses increase productivity and reduce costs.

Who is the Bimp production management system suitable for?

The ERP system is easy to implement and suitable for any product business, except offline retail.

For distributors

For manufacturers

For online stores

For importers

For warehousing business

For logistics companies

The Bimp production management system (MES module) is the perfect solution for:

- managers;

- automation and programming engineers;

- logistics and warehouse management specialists;

- operators and production line workers;

- research and development specialists;

- maintenance specialists.

What tasks does the Bimp accounting system solve?

The accounting system successfully addresses the basic needs of enterprises:

- Inefficient use of raw materials/materials. The Bimp system provides deep sales and profitability analytics. This allows identifying demand trends for specific products/items. It enables timely adjustment of the assortment and directing production capacities towards relevant products.

- Lack of accurate cost accounting. Information about the actual warehouse status in the ERP system is updated in real time.

- Difficulties with planning and forecasting. Bimp provides order planning for production and stock purchases in advance. Thanks to thorough analysis, the system creates accurate demand forecasts. You will be able to track plan fulfillment and adjust forecasting strategies based on actual results.

- Lack of coordinated work between departments. The Bimp ERP system unites all business departments into a single system and ensures continuous exchange of up-to-date data between departments (production, procurement, logistics, sales, etc.).

- Lack of understanding of downtime and malfunction causes. The accounting system generates deep analytics and tracks patterns causing downtime. For example, untimely deliveries and material mismatches or order volume overruns.

- Difficulties in documentation and reporting. Automatic creation and processing of documentation (invoices, acts, bills, etc.) significantly simplifies reporting. All documents are stored in electronic format.

Bimp production management system setup

The "Production" module consists of several important sections:

- Production order – the document defines the procedure for material write-off, the formation of the cost of finished products, and organizes production according to the plan

- Assembly and disassembly – documents that define the composition of finished products and allow automatic write-off of materials from warehouses, their quantity.

- Specifications – the calculation defines the composition of finished products, in particular the necessary materials and quantities for their automatic write-off and cost formation of the item.

Specifications setup

Forget about difficulties with accounting for raw materials and components. Thanks to the automated production management system, you will know the quantity of consumable raw materials and will be able to control costs at every stage of production. The specifications section defines the composition of finished products products and the quantity of necessary materials

for the automatic formation of the product cost. This document is an integral part of the production process and is necessary for creating and processing such documents as "production order", “assembly" and “disassembly".

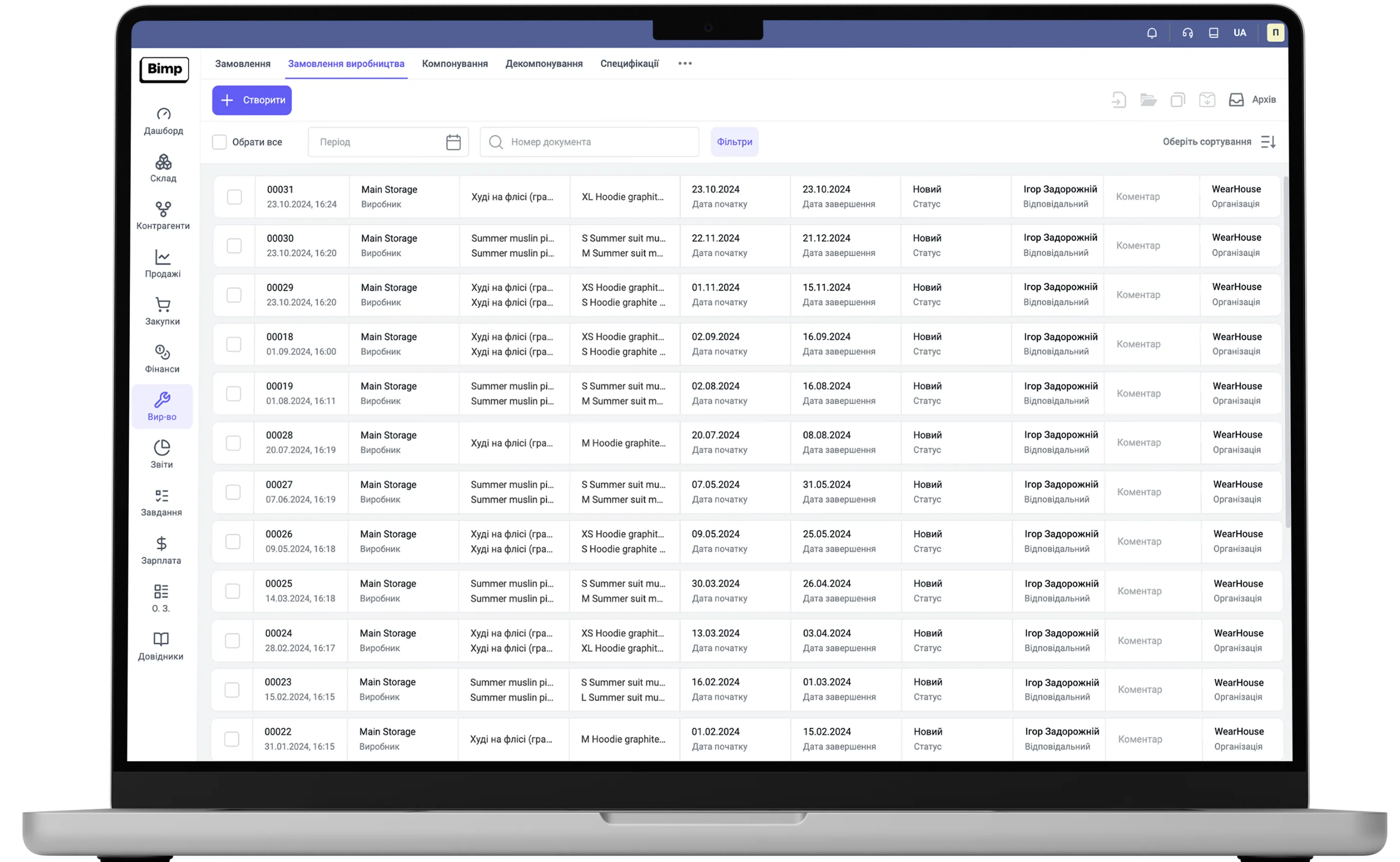

Production order setup

The document "production order" is key for planning production processes and allows you to form the cost of finished products. You will be able to easily create orders, specify necessary materials, resources, and deadlines.

When creating an order, all nomenclature and related information is automatically pulled from counterparty directories, price lists, and specifications, which greatly simplifies the process. Thanks to the intuitive interface, you will quickly add the necessary data: manufacturer, nomenclature, quantity of materials, planned cost, etc.

Configuring layout/decoupling

Document layout/decomposition allows you to define the composition of finished products and automatically write off materials from warehouses. Thanks to the assembly process, you can plan the composition of products, and disassembly allows you to return materials back to the warehouse if part of the product was not used.

Creating these documents in Bimp is as simple as possible: instead of manually entering each component, you can import an Excel file with a ready-made list of items for production.

Setup of cost price calculation

Cost price calculation in Bimp is an automated process that allows to accurately determine the expenses for manufacturing products, taking into account all components and materials. Thanks to integration with specification specifications, layout and disassembly it is convenient to perform precise accounting of expenses and quickly calculate the cost price of finished products. This approach reduces the risk of errors, improves financial planning, and helps effectively manage production costs.

Advantages of using the production management system from Bimp

Advantages of the Bimp ERP system for production:

- Automated process management allows reducing downtime in production, optimizing resource usage, and ensuring a continuous process.

- Accounting of materials and resources allows optimizing their use and reducing costs for raw materials and components, as well as minimizing supply disruptions. This advantage allows accurately calculating the cost price of products and reducing unnecessary expenses.

- Interaction between production lines, warehouses, financial and technical departments. This ensures uninterrupted information exchange and coordinated work of all units.

- Inventory, materials, and finished products control helps avoid shortages of raw materials or excess finished products in warehouses.

- Documentation automation significantly simplifies the control and audit process.

Production management based on the Bimp ERP system allows automating manufacturing processes, increasing planning and calculation accuracy, and reducing costs.

Intuitive interface and integration with other documents make the planning and production control process fast and error-free. Implement the ERP system to grow your business and optimize all production operations.

Free access to the Bimp ERP system

Try free access to the system for 14 days, all features will be available. Take advantage of this opportunity and explore the service. If you have any questions, you can always contact our support service.

Submit an application on the website right now and get a free consultation from our experts with a demonstration of the ERP system functionality. They will help you implement automated inventory management quickly and without unnecessary costs. Bimp company is always happy to help businesses!